Comparing HVAC Systems for Indoor Farming: The Ultimate Guide to a Thriving Indoor Crop Environment

Some of the links in this post are affiliate links. As an Amazon Associate, we earn a referral fee from qualifying purchases—at no extra cost to you.

Indoor farming isn’t just a trend—it’s a revolution. But even the most high-tech grow lights or nutrient-rich hydroponic setups can’t save a crop if your climate control is off. That’s where HVAC systems come into play. Choosing the right HVAC setup can be the difference between lush, green harvests… or wilting disappointment.

In this ultimate guide, we’re diving deep into the world of HVAC systems and how to choose the perfect one for your indoor farm. Whether you’re growing leafy greens in a warehouse or cultivating strawberries in your garage, this guide is for you.

Table of Contents

Why HVAC Systems Matter More Than Ever in Indoor Farming

The Unseen Hero Behind Indoor Crop Success

You probably already obsess over your lighting schedules or pH levels—but how often do you think about your HVAC system? Without it, your entire operation could crash. HVAC (Heating, Ventilation, and Air Conditioning) is what keeps your plants breathing, transpiring, and growing at their best.

Unlike outdoor farms, indoor farms don’t get natural ventilation or seasonal airflow. That makes HVAC systems the lungs of your grow space.

From Seed to Harvest—How HVAC Systems Impact Growth

Think of HVAC systems as the farmers working 24/7 behind the scenes. They manage:

- Temperature – Keeping your plants in the Goldilocks zone.

- Humidity – Too much = mold. Too little = wilted plants.

- Air movement – Preventing pests and ensuring even CO₂ distribution.

When these elements are in perfect harmony, your yields will thank you.

What Is an HVAC System in the Context of Indoor Farming?

HVAC vs Traditional Ventilation: What’s the Difference?

Most people think of HVAC as something for homes or office buildings. But indoor farming HVAC systems are on another level. They’re designed not just for comfort but to maintain tight environmental control.

Traditional fans and vents simply won’t cut it when your kale is gasping for fresh, CO₂-rich air at just the right temperature and humidity.

Temperature, Humidity, and Airflow—The Holy Trinity of Indoor Growth

A solid HVAC system for indoor farming will juggle:

- Stable temperatures (usually between 68°F–77°F)

- Relative humidity levels (50%–70%)

- Air exchanges every few minutes

These aren’t just suggestions—they’re survival stats for your crops.

Types of HVAC Systems for Indoor Farming

Split Systems: Small Scale, Big Results

Split systems are the underdogs of the HVAC world. Ideal for smaller grow rooms or hobby setups, they offer simple heating and cooling through a combination of an indoor air handler and an outdoor condenser unit.

Best Use Case for Split HVAC Systems

If you’re farming in a converted garage, bedroom, or small warehouse, a split system could be your wallet’s best friend.

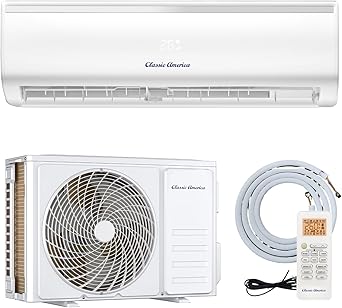

For small indoor farms, consider a reliable ductless system like the 12000 BTU Mini Split AC & Heat Pump. It offers both heating and cooling with quiet operation and energy efficiency—perfect for maintaining consistent grow conditions in compact spaces.

Packaged HVAC Systems: Space-Saving and Efficient

Packaged HVAC systems combine all components into a single outdoor unit, making them compact and efficient. They’re commonly used in commercial environments where space-saving is essential. These systems can be ducted to serve multiple indoor zones with consistent heating and cooling. This makes them a practical solution for growers looking to simplify their HVAC infrastructure.

Ideal Farms for Packaged Units

Packaged units are ideal for farms with limited space and straightforward climate control needs. If you’re operating in a single-zone setup, these systems offer an excellent balance of efficiency and simplicity. Their all-in-one design makes installation and maintenance easier for smaller operations. They’re a great starting point for indoor farmers aiming for scalability without complexity.

VRF/VRV Systems: Precision and Control

Variable Refrigerant Flow (VRF) and Variable Refrigerant Volume (VRV) systems are high-performance HVAC solutions. They provide individualized climate control across different zones within your indoor farm. These systems adjust refrigerant flow based on real-time demand, optimizing energy use and performance. Think of them as the luxury model of indoor farming climate control—powerful, smart, and precise.

Are VRF Systems Worth the Cost?

VRF systems do come with a higher upfront investment, but the long-term benefits often justify the cost. If your farm has diverse climate zones or sensitive crops, the control they offer is invaluable. Energy efficiency also improves significantly, lowering operational costs over time. For larger or more advanced indoor farms, VRF is a future-proof choice.

Chilled Water Systems: Industrial Strength Cooling

Chilled water systems use a central plant to circulate cooled water through air handlers or coils. This allows for powerful and even cooling across expansive growing areas. They are highly efficient when managing temperature for large-scale operations. Their industrial-grade capacity makes them ideal for farms needing serious climate control muscle.

Perfect for Multi-Zone Farming Facilities

If your farm includes multiple growing zones with varied climate needs, chilled water systems are a top-tier solution. They excel in vertical farming environments and commercial greenhouses with continuous production cycles. Their stability is especially valuable for crops requiring tight environmental tolerances. These systems are a cornerstone of professional indoor farming at scale.

Comparing HVAC Systems: Which One Suits Your Indoor Farm Best?

Efficiency Ratings and Energy Costs

Not all HVAC systems are created equal. Look for:

- SEER (Seasonal Energy Efficiency Ratio)

- EER (Energy Efficiency Ratio)

- COP (Coefficient of Performance)

Higher ratings = lower monthly energy bills. For indoor farming, this can save thousands annually.

Installation and Maintenance Requirements

Split HVAC systems are relatively simple to install, making them a popular choice for small-scale growers. However, they often require more frequent filter replacements to maintain optimal performance. On the other hand, VRF systems need professional installation due to their complexity. While maintenance is more involved, the long-term performance benefits make it worthwhile for serious growers.

Climate Control Precision and Stability

Some crops, like mushrooms or strawberries, require highly specific environmental conditions to thrive. For these, VRF or chilled water systems offer the micro-climate precision needed to maintain stability. If you’re growing less sensitive crops like leafy greens, a packaged HVAC unit may be sufficient. The key is matching your system’s capabilities to your crop’s unique requirements.

Cost Breakdown and ROI for Each Type

- Split systems: Low upfront cost, decent ROI

- Packaged units: Moderate cost, solid return

- VRF systems: High cost, high return for advanced growers

- Chilled water systems: Industrial-scale cost, enterprise-level ROI

The Role of HVAC in Pest and Mold Prevention

Moisture Control to Prevent Mold

High humidity creates the perfect environment for mold to thrive, which can devastate indoor crops. That’s why effective dehumidification is a critical function of any indoor farming HVAC system. It becomes especially important during flowering stages when plants release more moisture into the air. In tightly packed grow areas, poor humidity control can quickly lead to widespread mold issues.

Air Filtration to Keep Pests at Bay

HEPA filters and UV sterilization in ductwork can reduce pathogens and insect infestations dramatically—giving your plants a safe, clean space to thrive.

Pairing your HVAC with a high-efficiency air purifier like the LEVOIT Core 300 can help maintain air quality by trapping mold spores and tiny pests—ensuring your crops breathe clean, pathogen-free air.

Real-World Case Studies: HVAC Systems in Action

Small Urban Farm Using Split Systems

A microgreens startup in New York has adopted two ductless mini-split HVAC units to manage its indoor growing environment. These units offer efficient climate control without the complexity or cost of larger systems. Despite being in a bustling urban setting, the farm maintains a modest energy bill of just $400 per month. Impressively, their compact setup produces enough fresh greens to supply five local grocery stores each week.

Commercial Lettuce Operation with VRF System

In California, a commercial lettuce grower upgraded their 10,000 square-foot facility with a cutting-edge Variable Refrigerant Flow (VRF) system. This advanced HVAC solution allows precise temperature and humidity control across multiple grow zones. Since the installation, the farm has seen a 20% boost in crop yields. Even better, HVAC-related energy costs dropped by 30%, significantly improving their overall profitability.

Multi-Story Hydroponics Farm Powered by Chilled Water Units

A vertical hydroponic farm in Singapore operates across five stacked stories in a dense urban environment. To manage such a complex growing system, they utilize an industrial-grade chilled water HVAC system. This system keeps temperature fluctuations under ±0.5°C, ensuring stable conditions critical for delicate crops. The setup is especially vital for maintaining the purity and consistency of their pharmaceutical-grade basil production.

Common Mistakes When Choosing HVAC for Indoor Farming

Overlooking Air Exchange Needs

Fresh air = fresh growth. Don’t skimp on ventilation rates or ignore CO₂ needs. Plants need to breathe, too.

Underestimating Humidity Control

A top mistake? Thinking a standard air conditioner can handle humidity. Spoiler: It can’t. You’ll need dedicated dehumidifiers or integrated moisture control.

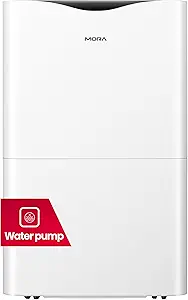

Need precise moisture control? Add a dedicated unit like the Mora 50 Pint Dehumidifier to your setup. It helps reduce humidity during critical growth phases, protecting your plants from mold and mildew.

Ignoring Energy Efficiency Ratings

Saving a few bucks upfront on an inefficient system will cost you more in the long run. Always check for ENERGY STAR® certification or equivalent.

How to Choose the Right HVAC System for Your Indoor Farm

Questions to Ask Before Buying

- What are my crops’ environmental requirements?

- How large is my grow space?

- Do I need multiple climate zones?

- What’s my power capacity?

The answers will guide you toward the right system.

Budget vs Performance: Finding the Sweet Spot

If you’re just starting out, don’t overcommit. A split system might serve you well. But if you’re scaling up? It might be time for a professional VRF setup or even a chilled water solution.

Bonus Tips for Maximizing Your HVAC System’s Potential

Smart Thermostats and Automation Tools

Integrating tools like smart controllers or apps can allow real-time adjustments, remote monitoring, and even predictive maintenance alerts.

Upgrade your climate control with a smart device like the ecobee Smart Thermostat. It integrates with most HVAC systems and provides real-time remote access, scheduling, and even voice control—perfect for hands-free growing.

Routine Maintenance Checklist

- Replace filters every 30–60 days

- Inspect ductwork for leaks

- Calibrate thermostats monthly

- Schedule professional HVAC checkups every season

Keep airflow clean and consistent by replacing your filters regularly. The Filterbuy 16x25x1 MERV 13 Filters trap allergens, mold spores, and fine particles—ideal for grow spaces demanding clean air circulation.

Future of HVAC in Indoor Farming

AI-Controlled Climate Systems

Artificial intelligence is rapidly becoming a game-changer in indoor farming. Machine learning algorithms can now analyze your crop’s growth patterns and environmental needs in real time. Based on this data, AI systems automatically adjust HVAC settings like temperature, humidity, and airflow. This leads to more efficient energy use and maximized crop performance without constant human intervention.

Sustainable and Green HVAC Innovations

Sustainability is driving major innovations in HVAC technology for indoor farming. Systems powered by geothermal energy and solar panels are reducing reliance on traditional energy sources. Some farms are even using waste heat recirculation to cut costs and environmental impact. These green solutions are not only better for the planet but also help farms operate more efficiently in the long run.

Conclusion: Making the Right HVAC Choice for Your Growing Success

When it comes to comparing HVAC systems for indoor farming, there’s no one-size-fits-all answer. But with the right knowledge, you can choose a system that saves you money, increases yield, and keeps your crops in perfect balance. Whether you’re just starting out or scaling up, never underestimate the power of precise climate control. Your plants are counting on it—and so is your profit.

FAQs on Comparing HVAC Systems For Indoor Farming

1. Can I use residential HVAC systems for indoor farming?

While it’s technically possible to use a residential HVAC system in a small grow room, it’s not recommended for serious indoor farming. Residential systems aren’t designed to manage the intense humidity, high CO₂ levels, or rapid heat fluctuations associated with indoor crop production. Over time, this can lead to inefficiency, higher energy bills, and increased maintenance. Purpose-built HVAC solutions are engineered to handle agricultural demands far better.

2. How does HVAC automation improve crop yield in indoor farms?

HVAC automation—especially when integrated with smart sensors and controllers—ensures real-time adjustments to temperature, humidity, and airflow. This consistency creates optimal growing conditions 24/7, leading to faster growth rates, healthier plants, and reduced crop loss. It also frees up labor and minimizes human error, making your farming operation more efficient and profitable.

3. What’s the impact of poor air circulation on indoor plants?

Poor air circulation can lead to stagnant air, uneven CO₂ distribution, and moisture buildup. This environment encourages mold, mildew, and pest infestations while also stunting plant growth. Proper ventilation and airflow are essential components of any HVAC system, ensuring plants receive fresh air and nutrients evenly across the grow area.

4. Are there energy-efficient HVAC solutions specifically for vertical farms?

Yes, energy-efficient HVAC systems like VRF/VRV units or modular chilled water systems are tailored for vertical farms. These systems can be zoned to meet specific microclimate needs on different growing levels, maximizing energy use while minimizing waste. Some setups also incorporate energy recovery ventilators (ERVs) and LED-linked HVAC controls to further reduce operational costs.

5. How do I size an HVAC system for my indoor farm?

Sizing an HVAC system depends on several factors including square footage, crop type, number of grow lights, insulation quality, and average heat load. A rough estimate uses BTUs (British Thermal Units), but for best results, a Manual J load calculation or consultation with a HVAC engineer experienced in indoor agriculture is highly recommended. Undersized systems struggle to maintain conditions, while oversized units cycle inefficiently, leading to increased costs and wear.

Other Useful Resources Related To Comparing HVAC Systems For Indoor Farming

- ASHRAE – HVAC Design for Indoor Agriculture

https://www.ashrae.org/technical-resources/standards-and-guidelines/standards-addenda/hvac-design-guide-for-indoor-agriculture

ASHRAE is a global authority on HVAC systems and their publication specific to indoor farming is essential for design and engineering considerations. - Controlled Environment Agriculture (CEA) by USDA

https://www.nal.usda.gov/legacy/afsic/controlled-environment-agriculture-cea

This USDA page provides context on how HVAC systems fit into larger controlled environment agriculture (CEA) practices. - Greenhouse Management – HVAC & Dehumidification

https://www.greenhousemag.com/article/hvac-dehumidification-tips/

This article offers insights on moisture management in indoor environments, a key element of HVAC system design. - Growlink – Smart HVAC Automation for Indoor Farming

https://growlink.com/blog/smart-hvac-automation-for-indoor-agriculture

Growlink discusses how automation technology integrates with HVAC systems for optimized climate control in indoor farms. - Hydroponics Research & Indoor Air Quality by EPA

https://www.epa.gov/indoor-air-quality-iaq/indoor-air-quality-and-indoor-agriculture

The U.S. Environmental Protection Agency’s page on indoor air quality ties directly into the importance of HVAC for plant and human health in indoor farming.