Robotic Harvesting in Indoor Farming

In today’s rapidly evolving agricultural landscape, indoor farming has emerged as a groundbreaking solution to the challenges posed by traditional farming methods. One key aspect of indoor farming is the implementation of robotic harvesting, which has revolutionized how crops are cultivated and harvested. In this article, we will explore the concept of robotic harvesting in indoor farming and delve into its benefits, applications, and future prospects. Join us as we uncover the fascinating world of automated crop harvesting and its potential to shape the future of agriculture.

Table of Contents

Introduction

Imagine a world where the constraints of seasonality or climate do not limit agriculture. A world where crops can be grown efficiently and sustainably within the controlled environment of indoor farms. This vision is becoming a reality with the advent of indoor farming. This practice harnesses technology to cultivate crops in optimized conditions. Robotic harvesting is at the forefront of this agricultural revolution, a cutting-edge technique that combines automation and precision to streamline the harvesting process. By replacing manual labour with advanced robotics, indoor farms can achieve unprecedented efficiency, crop quality, and sustainability.

The Rise of Indoor Farming

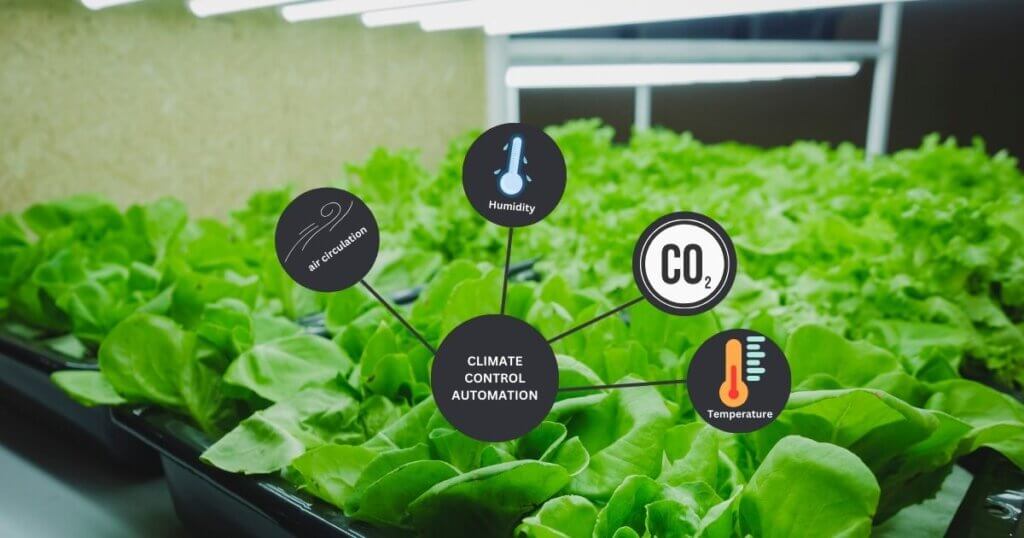

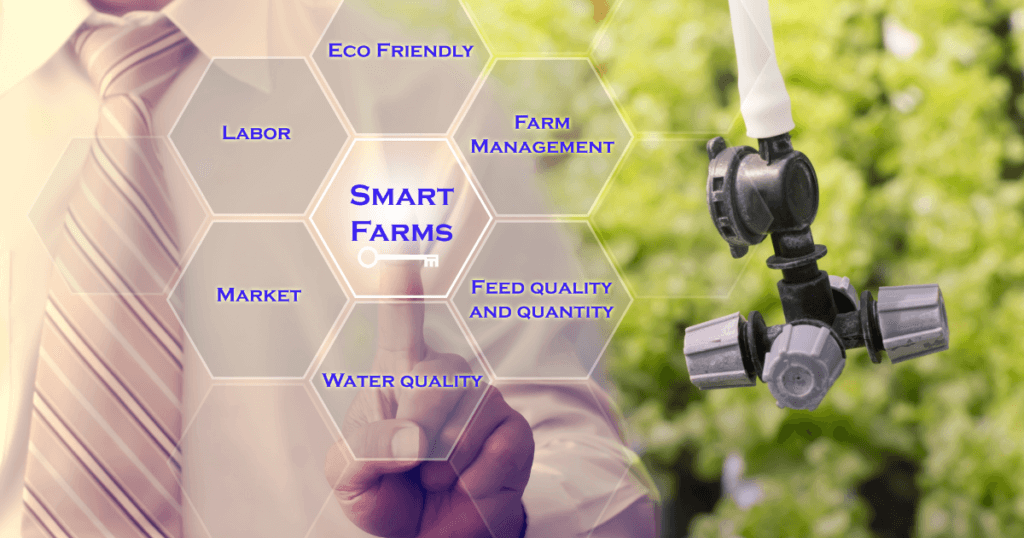

Over the past decade, indoor farming has grown exponentially and garnered significant attention within the agricultural industry. This alternative farming method involves cultivating crops within enclosed structures such as greenhouses or vertical farms, where environmental factors such as light, temperature, and humidity can be meticulously controlled. The controlled environment mitigates the risks associated with traditional farming, such as adverse weather conditions, pests, and diseases, enabling year-round crop production. As indoor farming continues to gain traction, integrating robotics has emerged as a transformative solution to address the labour-intensive nature of harvesting.

Understanding Robotic Harvesting

Robotic harvesting refers to the use of robotic systems to automate the process of gathering crops from indoor farms. These sophisticated machines are equipped with advanced sensors, computer vision technology, and robotic arms capable of delicately manipulating plants and fruits. By leveraging artificial intelligence and machine learning algorithms, robots can recognize ripe produce, precisely maneuver through dense foliage, and delicately harvest crops without causing damage. The ability of robotic harvesters to replicate human-like dexterity and discernment has made them indispensable in indoor farming.

FarmBot Express V1.1 is an open-source, precision robotic gardening system that automatically plants, waters, and monitors crops. Ideal for tech-driven indoor agriculture.

The Benefits of Robotic Harvesting in Indoor Farming

Enhanced Efficiency and Productivity

Robotic harvesting offers many benefits that significantly enhance the efficiency and productivity of indoor farming operations. By automating the labour-intensive task of harvesting, robots can work tirelessly around the clock, ensuring a continuous and uninterrupted workflow. Unlike human workers, who require breaks and rest periods, robots can operate non-stop, maximizing the output of the indoor farm. This increased productivity translates into higher yields and shorter harvesting cycles, enabling farmers to meet the ever-growing demand for fresh produce more efficiently.

Improved Crop Quality and Consistency

One of the primary advantages of robotic harvesting is the ability to ensure consistent crop quality. Robots are programmed to detect and select only ripe produce, eliminating the risk of harvesting unripe or damaged crops. This precision ensures that only the highest-quality fruits and vegetables reach the market, enhancing consumer satisfaction and reducing food waste. Furthermore, the gentle handling of crops by robotic arms minimizes bruising or mechanical damage, preserving the harvested produce’s visual appeal and nutritional integrity.

Cost Savings and Sustainability

Robotic harvesting presents a compelling economic case for indoor farmers. Although the initial investment in robotic systems can be substantial, the long-term cost savings outweigh the upfront expenditure. Farmers can reduce labour costs and reallocate resources to other critical aspects of the operation by eliminating the need for manual labour. Additionally, robotic harvesters optimize resource utilization by harvesting only mature crops, reducing water and fertilizer waste. The controlled environment of indoor farms also minimizes the use of pesticides and herbicides, promoting sustainable farming practices and reducing the environmental impact of agriculture.

Applications of Robotic Harvesting in Indoor Farming

Robotic harvesting finds application across various crops cultivated in indoor farming setups. Let’s explore some of the key areas where this technology has made a significant impact.

Leafy Greens and Vegetables

Robotic harvesting has proved particularly effective in cultivating and harvesting leafy greens and vegetables. The delicate structure and precise timing required to harvest these crops make them well-suited for automation. Robots equipped with computer vision technology can identify mature leaves and carefully cut them without damaging the plant. This streamlined process reduces the reliance on manual labour. It ensures consistent quality across harvested greens, enhancing the overall efficiency of the indoor farm.

AeroGarden Bounty Elite is a countertop hydroponic garden that automates lighting, watering, and nutrients — great for growing leafy greens indoors with minimal human intervention.

Fruits and Berries

Harvesting fruits and berries has traditionally been a labour-intensive and time-consuming task. Robotic harvesters have revolutionized this process by automating the delicate picking of ripe fruits. Advanced sensors and computer vision technology enable robots to assess the ripeness of each fruit and employ gentle gripping mechanisms to harvest them without causing harm. By significantly reducing the time and effort required for fruit harvesting, robots enable indoor farms to scale up production and meet the growing demand for fresh and delectable fruits.

Growneer 3-Pack Strawberry Grow Bags allow controlled indoor berry cultivation and are compatible with harvesting tools or compact robot attachments.

Controlled Environment Agriculture (CEA)

Robotic harvesting plays a pivotal role in Controlled Environment Agriculture (CEA). CEA refers to cultivating crops in environmentally controlled structures, such as greenhouses or vertical farms. Integrating robotic systems in CEA allows for precise monitoring and manipulation of the growing conditions, ensuring optimal plant growth and development. Robotic harvesters complement this approach by seamlessly transitioning from the cultivation phase to the harvesting phase, enabling a fully automated indoor farming ecosystem.

Inkbird WiFi Temperature and Humidity Controller is a smart device for monitoring and automating temperature and humidity in greenhouses or indoor farms.

Future Prospects and Advancements in Robotic Harvesting

As technology continues to advance, the future of robotic harvesting in indoor farming holds immense promise. Here are some key areas of development that are poised to shape the evolution of this technology.

Artificial Intelligence and Machine Learning

Integrating artificial intelligence and machine learning algorithms into robotic harvesters will make them increasingly sophisticated and intelligent. Robots can enhance their decision-making capabilities by continuously analyzing vast amounts of data, improve crop recognition, and adapting to dynamic environmental conditions. This advancement will increase indoor farming operations’ efficiency, precision, and adaptability.

NVIDIA Jetson Nano Developer Kit is a mini-computer optimized for AI and machine learning — ideal for developing smart farming bots and vision systems.

Swarm Robotics and Collaborative Harvesting

Swarm robotics involves the coordination of multiple robots to perform complex tasks collectively. In the context of robotic harvesting, swarm robotics can revolutionize the efficiency and scalability of indoor farming. Robots can distribute the workload, communicate seamlessly, and synchronize their movements by working collaboratively. This approach allows for faster and more efficient harvesting, making it easy to tackle larger crop volumes.

Integration of Sensing Technologies

The integration of advanced sensing technologies, such as hyperspectral imaging and near-infrared spectroscopy, can enhance the capabilities of robotic harvesters. These technologies enable robots to assess crop health, detect diseases or pests, and make informed decisions about harvesting. By leveraging real-time data and sophisticated algorithms, robots can optimize the timing and method of harvesting, leading to higher yields and improved crop quality.

Apogee MQ-500 PAR Light Sensor is a high-precision light sensor to measure Photosynthetically Active Radiation (PAR) — useful in automated light monitoring systems.

Conclusion

Robotic harvesting represents a significant advancement in indoor farming, offering unparalleled efficiency, precision, and sustainability. Robotic harvesters have transformed how crops are cultivated and harvested in controlled environments by seamlessly combining automation, artificial intelligence, and advanced sensing technologies. The benefits of this technology extend beyond increased productivity and cost savings, encompassing improved crop quality, reduced food waste, and environmental stewardship. As the agricultural industry continues to embrace innovation, the future of robotic harvesting holds immense potential to shape a more sustainable and food-secure world.

FAQs – Robotic Harvesting

1. What types of crops are best suited for robotic harvesting?

While robotic harvesting can be used for various crops, certain types are more suited for automation. Leafy greens, herbs, tomatoes, strawberries, and other small fruits are ideal because they grow in controlled environments and can be easily identified and picked by robotic arms. Crops requiring delicate handling or precision harvesting tend to benefit the most from robotic automation.

2. How do robotic harvesters differentiate between ripe and unripe produce?

Robotic harvesters utilize advanced sensors, including computer vision, hyperspectral imaging, and machine learning algorithms, to assess ripeness. These technologies analyze factors such as color, size, texture, and even internal composition to determine the best time for harvesting, ensuring only ripe produce is collected.

3. What are the main challenges of implementing robotic harvesting in indoor farming?

Some key challenges include the high initial cost of robotic systems, the complexity of integrating AI-driven technology into existing farming infrastructure, and ensuring adaptability for different crop types. Additionally, continuous maintenance and software updates are required to improve precision and efficiency over time.

4. Are there any regulatory considerations for using robotic harvesting technology?

Yes, regulatory considerations vary by region and industry. Indoor farms using robotic harvesting must comply with food safety standards, worker safety regulations, and agricultural technology guidelines. In some cases, AI-driven agricultural systems may also require compliance with data privacy laws if they collect and process large amounts of operational data.

5. How does robotic harvesting contribute to food security?

Robotic harvesting enhances food security by enabling consistent, year-round crop production in controlled environments, reducing reliance on unpredictable climate conditions. By minimizing food waste through precision harvesting and optimizing resource use (such as water and nutrients), robotic systems help produce more food with fewer resources, supporting global food sustainability efforts.

Other Useful Sites Related To Robotic Harvesting

- FarmBot:

FarmBot is an open-source precision agriculture project that integrates robotic technology into farming. It offers a Cartesian coordinate robot farming machine capable of performing various tasks such as sowing, watering, and mechanical weed control, all of which are essential for indoor farming environments. FarmBot is designed to operate indoors, outdoors, and in covered areas, making it versatile for different farming setups. - iFarm:

iFarm is an international company that develops software and hardware for vertical farming and hydroponics. Their technologies are used for automated, pesticide-free cultivation of salads, strawberries, and microgreens. iFarm’s systems rely on automation, sensors, and proprietary farm management software to monitor and automate crop care, integrating robotics to enhance efficiency in indoor farming operations. - Autonomous Technology in Agriculture:

This article discusses the introduction of autonomous technology, including robotic arms for tasks like berry picking, into agriculture. It highlights the potential of robotics to address labor shortages and reduce environmental impacts in farming. However, it also notes the challenges in achieving the dexterity and precision of human workers, which are crucial for tasks like harvesting delicate crops. - Larry Ellison’s Agricultural Venture:

An article from The Wall Street Journal examines Larry Ellison’s agricultural project, Sensei Ag, on the Hawaiian island of Lanai. The venture aimed to revolutionize farming through cutting-edge technology, including robotics. However, it faced operational setbacks, highlighting the complexities involved in implementing robotic solutions in farming. - Robotic Harvesting Developments:

This piece from the Associated Press explores the advancements in autonomous technology within agriculture, focusing on robotic harvesting. It discusses the potential benefits of robotics in addressing labor shortages and improving efficiency in indoor farming. The article also touches upon the challenges of replicating human dexterity and precision with robotic systems.